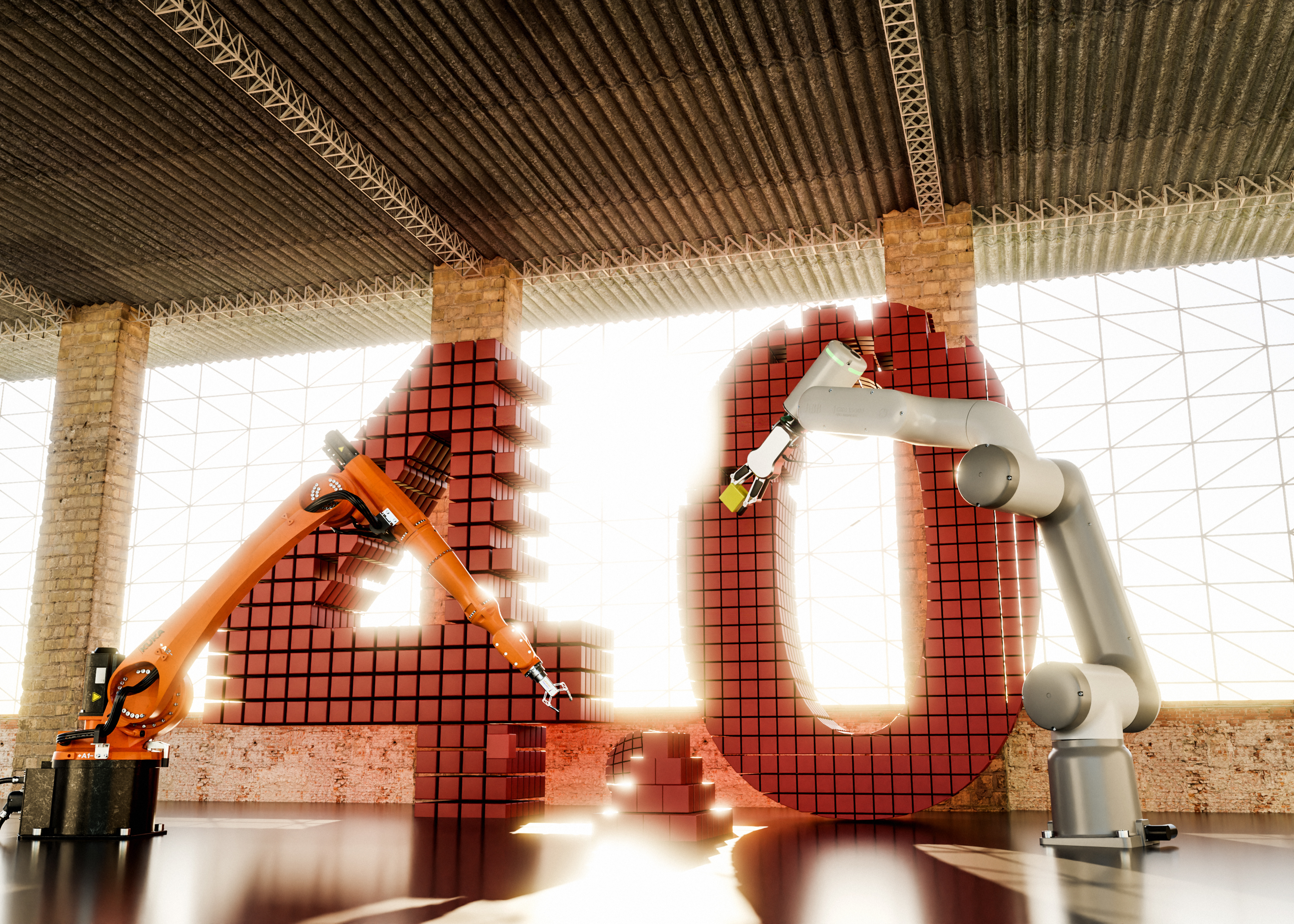

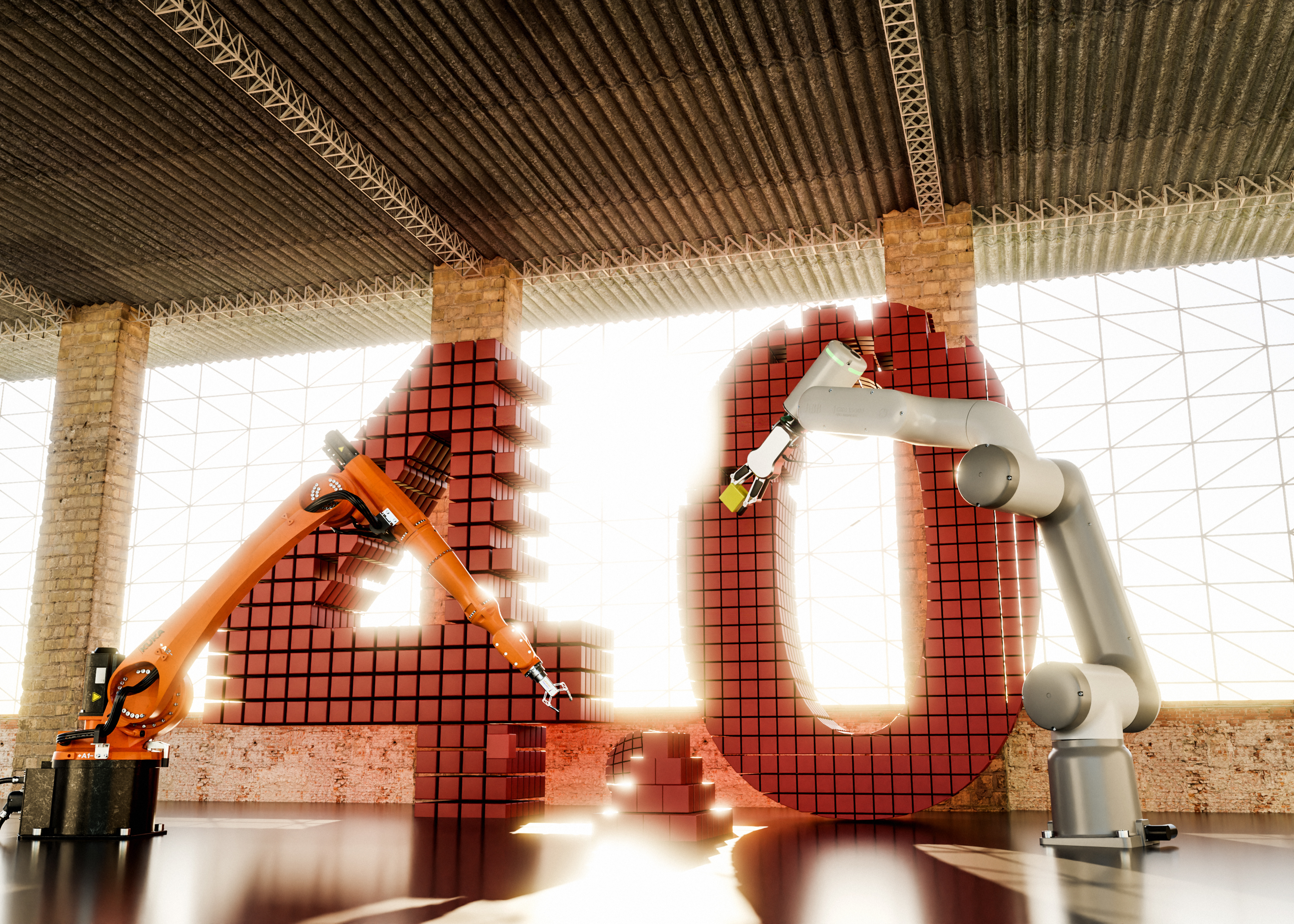

Industry 4.0 Solutions

Empowering your business with cutting-edge automation, digital transformation, and smart manufacturing solutions.

Empowering your business with cutting-edge automation, digital transformation, and smart manufacturing solutions.

We are at the forefront of the fourth industrial revolution, delivering innovative solutions that bridge the gap between physical and digital manufacturing.

Founded with a vision to revolutionize industrial processes, 16 Bits specializes in implementing Industry 4.0 technologies that enhance efficiency, productivity, and competitiveness.

Our team of experts combines deep technical knowledge with practical industry experience to deliver solutions that are both innovative and reliable.

Smart solutions

Precision engineering

Seamless integration

Custom development

Comprehensive solutions tailored to meet the evolving demands of modern industry.

Implementing robotic systems for precision manufacturing, assembly, and material handling to increase productivity and reduce human error.

Designing, programming, and implementing industrial control systems for seamless process automation and real-time monitoring.

Transforming raw data into actionable insights with advanced analytics, predictive maintenance, and automated reporting solutions.

Building secure, high-performance industrial networks that enable seamless communication between machines, systems, and people.

Custom software solutions tailored to your manufacturing needs, from MES systems to machine-specific applications.

Modernizing CNC machine tools with advanced controls, monitoring systems, and data collection capabilities.

Explore some of our recent implementations that are transforming industries.

Implemented a fully automated assembly line with robotic welding, vision inspection, and real-time quality control for a leading automotive manufacturer.

Developed a GMP-compliant automated packaging line with track-and-trace capabilities, increasing throughput by 40% while maintaining 99.9% accuracy.

Designed and implemented a hygienic automation system for a food processing plant, integrating weighing, sorting, and packaging with full traceability.

Deployed an IoT-based energy monitoring system across a manufacturing facility, reducing energy consumption by 22% through predictive analytics.

Connect with our team of Industry 4.0 experts to discuss how we can help you achieve your automation and digital transformation goals.